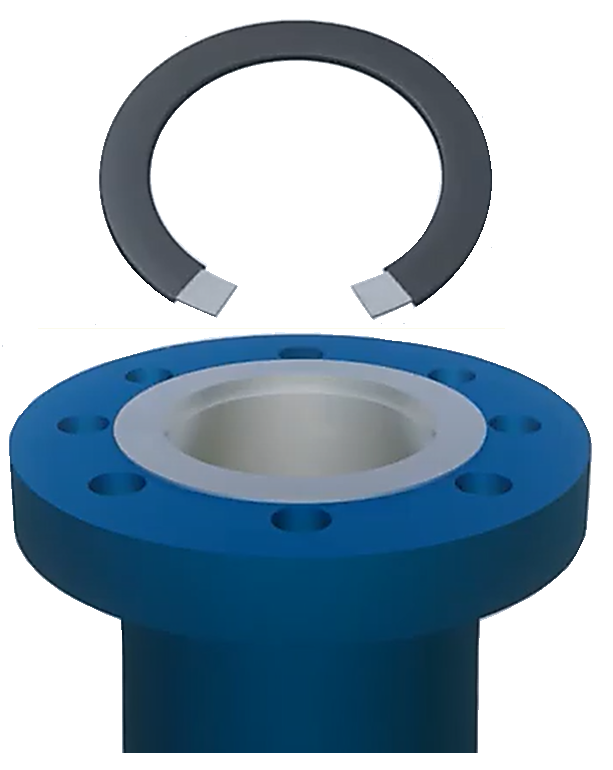

STEEL RUBBER GASKET. SRG G-S-S.

GET IN TOUCH

Talk to our dedicated expert on utility flange connections

For many years William Johnston & Company Limited has produced highly compliant gaskets for the UK water utilities sector. Our name is associated with integrity and all that we do is quality driven. To allow a tighter seal to be made we offer a tapered design steel EPDM gasket that is capable of 50% more maximum gasket stress than a standard 70 Shore A EPDM. EN13555 tested to address multiple areas that are essential from a gasket and high integrity sealing perspective.

- Minimum stress to seal

- Relaxation

- Modulus of elasticity

- Compression curve

- Maximum gasket stress

- Leakage

Reliance on Compliance

We assume that a gasket supplied is fit for purpose. At William Johnston & Company Limited we ensure that what is supplied meets or exceeds the basic criteria.

- Dimensions to DIN EN 1514. Flanges and their joints – Dimensions of gaskets for PN-designated flanges – Part 1: Non-metallic flat gaskets with or without inserts

- WRAS Approved

- W270

- DIN EN 681-1 compliant

- ISO 9624

- EN13555 tested to 40 Bar

Appropriate Installation

Ensuring correct installation is as important as having the correct gasket for the application. EUSR approved training combines theoretic knowledge and practical skills on flange gasket installation with a specific emphasis, where required, on water utility connections. Endorsing Best Available Techniques and addressing real life installation scenarios. This is a digitised system and so clarity on who, when and where is available alongside many other quality of installation control methods.

Bolting

Alongside the appropriate gasket and installation we offer fasteners. Grade of fastener is pertinent to the application and the chosen gasket. Constraints on bolt strength may have to be considered in line with the chosen flange material. Chemical, physical and dimensional properties of fasteners are essential to correct and long lasting flange connections. In compliance with BS EN ISO 898-1, ISO 898-2, DIN 931, DIN 601, DIN 555, DIN 125A and of course ISO 106814:2004 and WIS 4-52-03.

More Information?